Views: 2 Author: Julong Publish Time: 2022-08-09 Origin: aluminum panel systems manufacturer

What is punched aluminum plate? In fact, punching aluminum plate is a kind of aluminum plate that is punched on the aluminum plate by the aluminum plate processing plant using professional processing equipment, and the surface is processed by fluorocarbon or powder spraying process through numerical control bending edge. Due to the existence of holes, the texture of punched aluminum plates is lighter than other types of aluminum plates. The punched aluminum plate is not only beautiful in appearance, but also resistant to high temperature, corrosion and fire The moisture-proof feature can also moderately reduce the noise, mainly because the existence of holes can allow the sound wave to pass through and then weaken the sound intensity. So, how much does the customized perforated aluminum plate cost per square meter?

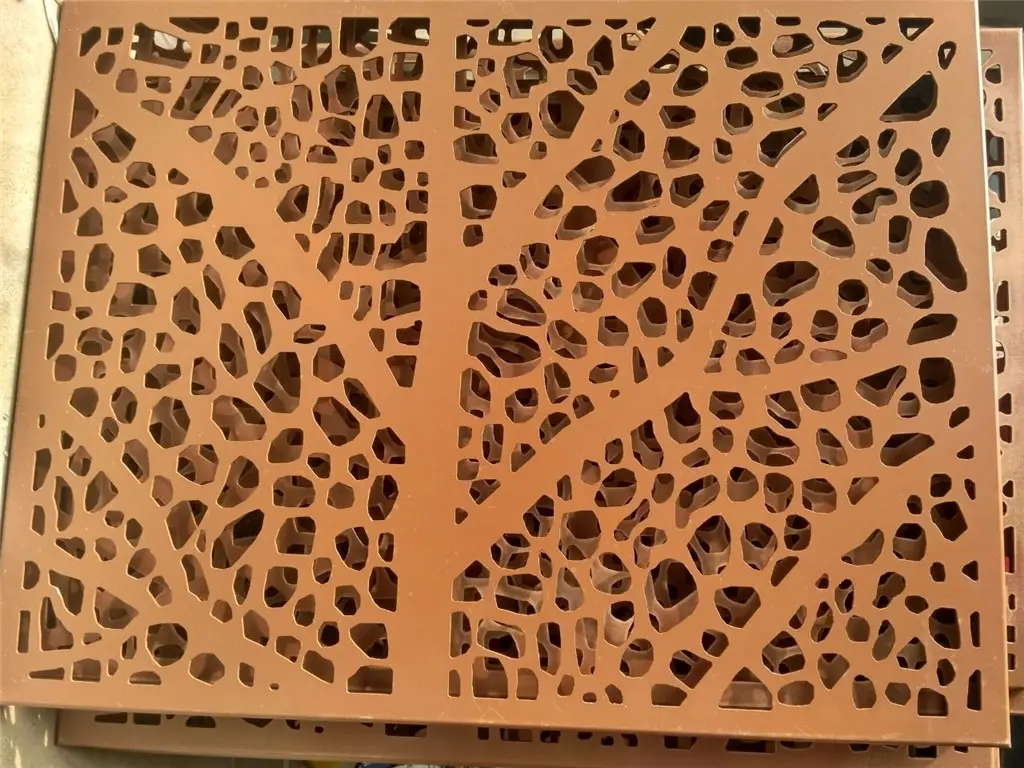

1. Hole shape of punched aluminum veneer

In the real scene, the most we can see is the circular punched aluminum veneer. Round is the most commonly used and most frequently used hole in punched aluminum plate. Of course, there are others, such as squares and triangles It can be seen that the hole shape of punched aluminum veneer is not limited to these shapes. It can be said that professional punched aluminum veneer manufacturers can customize any shape according to the needs of customers.

2. Hole spacing of punched aluminum veneer

You know what? The hole pitch of punched aluminum plate mainly refers to the diameter of the hole. The round hole distance is the most commonly used, among which the punching aluminum plate 3.0mm.4.0mm.5.0mm is the most commonly used hole distance, and its products have better cost performance. If the hole spacing is smaller, the price will be higher, because as a punching aluminum veneer manufacturer, it takes a relatively long time to produce traditional aluminum veneers in the processing and production process.

3. Punching thickness of aluminum veneer

The thickness of punched aluminum plate generally refers to how thick the aluminum alloy plate is selected to process the punched aluminum plate. The premise is to know where the product is ultimately used. If it is applied to the exterior wall of University Airport, high-speed railway station and commercial center, it is recommended to use 2.5mm and 3.0mm thick aluminum veneer to make stamped aluminum veneer; If used for interior decoration, thin stamped aluminum veneer can be used. 1.5mm or 2.0mm is recommended.

4. Punching rate of punching aluminum veneer

The punching rate of punched aluminum veneer refers to the punching rate on an aluminum veneer. Some require only a few holes for decoration, while others require password holes for shape. It can be seen that the price of punched aluminum veneer with different punching rates will also rise. The lower the punching rate, the cheaper the price. Therefore, it is necessary to determine the price of customized punched aluminum veneer in combination with the customer's engineering drawings.

5. Punching aluminum veneer modeling style

For the modeling style of stamped aluminum veneer, customization will be more extensive. Generally speaking, the stamping shape is carried out on the aluminum veneer, and some shapes can also be made directly using the stamped aluminum veneer. Any type of aluminum veneer shape can directly contact the stamped aluminum veneer manufacturer.