Views: 9 Author: Julong Publish Time: 2022-11-22 Origin: aluminum panel systems manufacturer

(1) Curtain wall engineering materials, design, manufacture, installation construction, and project quality approval should all adhere to safe and dependable, practical and beautiful, and economical and reasonable principles. Implementation of industry standards JGJl33-2001 "metal and stone curtain wall engineering requirements," 03J103-5 "aluminum composite panel (frame) curtain wall," and GB50210 2001 "building decoration project quality acceptance specification," as well as other related regulations, is required.

(2) The curtain wall and its connections must have enough bearing capacity, rigidity, and displacement capacity in comparison to the main structure. Curtain wall frame column connection metal angle code and other connections should be secured, and anti-loosening measures should be in place.

(3) The curtain wall's fire performance requirements should be following the current national standards "Architectural Design Fire Code" (GBJ16) and "Fire Code for High-Rise Building Design" (GB50045).

(4) The design requirements must be met for the main structure and curtain wall connection of various pre-buried pieces, as well as their number, specifications, position, and anti-corrosion treatment. Pollution, available neutral detergent or alcohol gently clean, avoid cleaning with a strong acid or strong alkaline detergent.

(5) The aluminum alloy profile's wall thickness at the connecting and hanging of the unit curtain wall should be calculated. It should be 5mm.

(6) Pre-buried pieces should connect the curtain wall's metal frame to the main construction. When the concrete construction is completed, pre-embedded elements should be buried in the main structure. When it is not possible to use pre-buried connections. Other trustworthy connection measures should be used, and their load-bearing capacity should be determined.

(7) The column shall be bolted to the corner code's edge, and the bolt diameter should be calculated to be 10mm. Insulating spacers should be utilized to separate the various metals in contact.

(8) The treatment of seismic joints, expansion joints, settlement joints, and other curtain wall components should assure the joints' usage function and the integrity of the finishes. The curtain wall project should be designed to fulfill the needs of maintenance and cleaning.

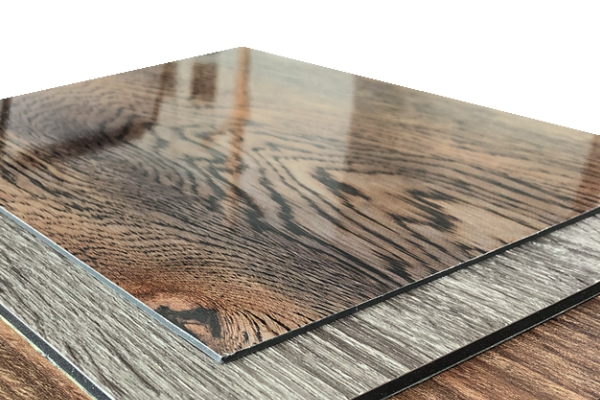

(9) The curtain wall project's major materials include skeleton materials, plates, sealing, and caulking materials of three categories. The engineering materials chosen should meet the requirements of national or pending industry standards. Should have a manufacturing certificate, and the material's physical mechanics and weather resistance should match the design specifications. The technical requirements of the exterior wall panels, which aluminum composite panel thickness of the upper and lower two layers of aluminum panels are 0.5mm; surface coating using fluorocarbon resin content I> 75%; film thickness 25m; l80. peel strength 7.0N / mm is particularly important.

(10) As a neutral silicone weatherproof sealant, sealant caulking adhesive should be utilized. Sealant application and a report on the compatibility of the materials contacted. Curtain wall performance must meet wind pressure deformation, air permeability, rain leakage, and other design requirements.