Views: 6 Author: Julong Publish Time: 2023-01-09 Origin: aluminum panel systems manufacturer

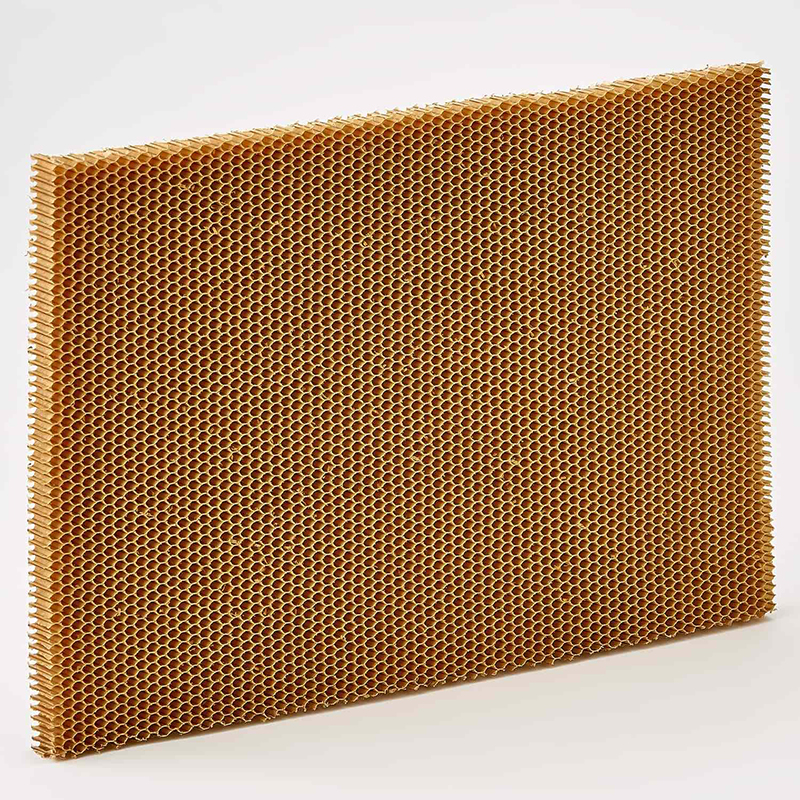

Nomex honeycomb is a structural core material that can be used in advanced composite sandwich panels and laminates.

1. Combine with prepreg

The sandwich panel is lightweight and stiff due to the usage of Nomex honeycomb as the sandwich core material and the surface layer being created with carbon fiber prepreg.

The adhesive composition and bonding performance of the prepreg material determine whether a resin adhesive layer is required in the laminate created by this technique. The inner and outer surface layers, as well as the adhesive film, can be cured concurrently or in stages. For example, the inner and outer surface layers are cured first, followed by the bonding of the surface layer to the core layer. Curing in a single pass allows the resin in the prepreg to join the reinforcement and the core.

2. Hand Paste Molding and Vacuum Bagging

The usage of Nomex honeycomb with prepregs is well recognized. However, Nomex honeycomb can be used with as acceptable results in the simpler hand gluing or vacuum bagging processes.

Wet-molding the surface layer with glass or carbon fibers and epoxy resin is a simpler approach to creating a very light Nomex honeycomb panel. Apply the release cloth to the surface layer's non-molded side (so that it adheres firmly to the honeycomb) and pull off the release cloth after curing it to bond the honeycomb. Mix some epoxy resin and apply it to the surface layer, impregnating the honeycomb with adhesive. Brush resin on regions that require bonding but not on places that do not require bonding. The honeycomb is then placed on top and let to cure. After curing, the resin is brushed on the opposite side of the honeycomb repeatedly, and the brushed resin is flowing onto the opposite side by weight.

3. Is the resin infusion process appropriate?

Nomex's open cell structure (similar to an aluminum honeycomb) makes it unsuitable for resin infusion operations. If a Nomex laminate is filled with resin, the Nomex honeycomb will be filled with resin as well. If you must use a laminate with Nomex honeycomb and resin infusion, then first resin infusion cures the surface layer and then bonds it to the Nomex honeycomb.