Views: 24 Author: Julong Publish Time: 2022-07-14 Origin: aluminum panel systems manufacturer

5 Tips for Aluminium Composite Milling

How can you improve the machining of aluminium composite materials?

What is aluminium composite ?

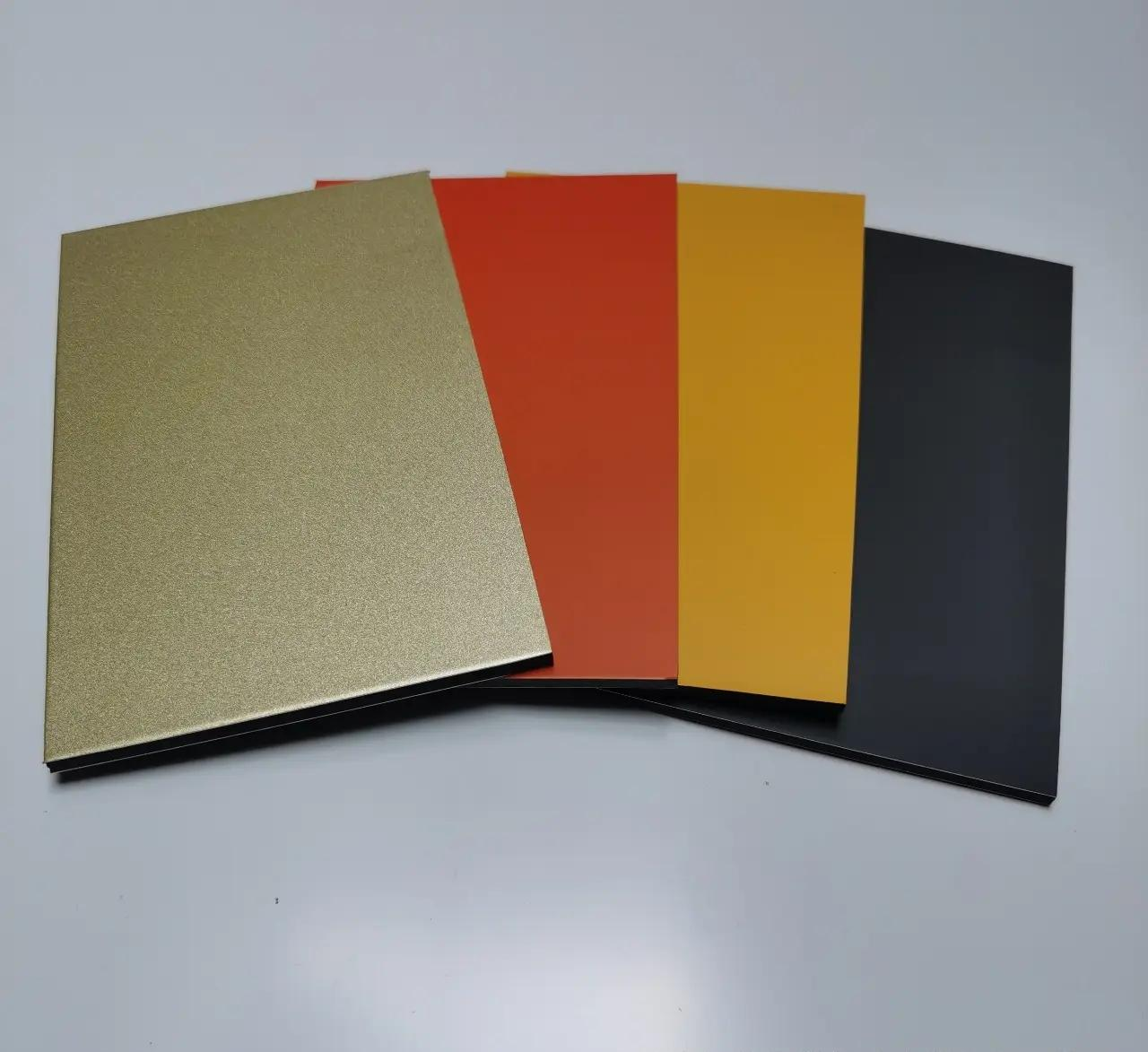

An aluminium composite panel is composed of two aluminium sheets and an inner core, usually made of a thermoplastic material.

Those materials are light, strong and nice to see.

Types of aluminium composites

Examples of aluminium composites that we can find on the market are Alucobond, Dibond, and many more.

Moreover, another big difference between types of aluminium composite is the material of the core, like plastico or fire resistant materials.

Machining aluminium composites materials

The operations on the aluminium composites materials that you can make with your CNC router are mainly:

· cnc cutting

· v-grooving (v-shaped channel)

· drilling

· engraving

5 free tips for aluminium composite machining

In this article we want to give you 5 free tips for aluminium composite cnc machining, directly from our CEO and founder, Mr Giulio Fazzini Giulio founded Protek CNC in Italy 30 years ago.

1. Minimize chips

Work with a climb milling. This means towards the direction of the rotation of the tool. In this way the first part of the chip is bigger that the end.

Also the parameters (feeds and speeds) of the machining have to be the right ones.

Our team of experts is available for giving you the consulting on the right parameters to machine ACM.

2. Gradual entry

The tool had to penetrate the material gradually, with an helical entry and 20° angle.

A straight entry could cause a stress on the material and on the grip of the panel .

Of course we are assuming that you are using a CNC router with vacuum blocking system.

3. The right tool

The right milling tool in the right way is very important because aluminium composite materials can be very abrasive.

Being very abrasive can cause a reduction of the performances of the milling tool.

4. Cleaning of the worktable

The cleaning of the worktable is very important because dust and chips can damage the quality of the finished product.

Be sure to use of a cnc machine with a very good suction system to have a clean work environment.

5. Final tip

These tips will help you manufacture a product made of aluminium composite, that will be highly competitive in the market.

Maybe the most important aspect than influences the quality of the products is the right balance between speed and grip

Feel free to ask suggestion from our team of experts to manage the right balancing of the various parameter.

Conclusions

We hope you have enjoyed the article, and we also hope you found what you were looking for.

Protek CNC manufactures innovative and avanced cnc routers for various materials

Many years of experience in aluminium composite panels machining made Protek CNC a top brand in the cnc market.

Aluminium Composite Panel Harga Price Trends: What To Expect in 2024?

Is Aluminium Composite Panel Weather-Resistant for Gold Coast Conditions?

How Can An Aluminum Honeycomb Supplier Help Improve My Product's Performance?

What Makes Aluminum Honeycomb Substrate Ideal for Composite Structures?

How Can I Get A Quote From Leading Aluminum Honeycomb Sheet Suppliers?

How Much Do Aluminum Honeycomb Sheets Cost Per Square Meter?

What Is The Cost of Aluminum Honeycomb Sandwich Panels And Are They Worth It?