Views: 202 Author: Julong Publish Time: 2023-06-13 Origin: aluminum panel systems manufacturer

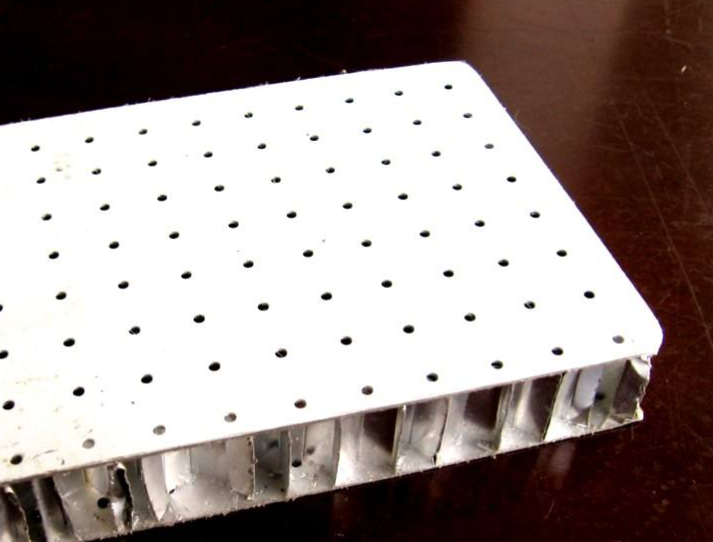

Why are aluminum honeycomb panels required to have perforations, and what purpose does each perforation serve? Multiple holes are processed into perforated aluminum honeycomb panels as needed, a layer of sound-absorbing material is put underneath the panel, and the panel is then manufactured using a composite technique. The primary components of a punched aluminum honeycomb panel are a perforated plate, a backing plate, and a honeycomb core. The perforated plate and backing plate are firmly attached to the honeycomb core using strong glue. What purpose does a perforated aluminum honeycomb panel serve then?

1. Perforation can enhance the ornamental qualities of aluminum honeycomb panels. Some people could wonder if a panel is not lovely if it is not perforated. The hole aluminum honeycomb plate is also a form of beauty, are two entirely different beauties, just like an ingredient with different cooking ways, producing a different taste to enjoy. There is no perforated aluminum honeycomb plate that will unquestionably not have the effect of unevenness.

2. Perforated can absorb sound; aluminum honeycomb plate peculiar honeycomb structure; sound from hole inhaling; must step in honeycomb core groove once; the sound will not travel through the outside world; will be again from the small hole out, when the sound shell has vanished. The perforated aluminum honeycomb panel's soundproofing riddle.

3. Perforation can absorb heat and preserve heat. In high-temperature seasons, perforated aluminum honeycomb panels can absorb a portion of the heat energy into the honeycomb core slot stored in the board. In cold seasons, perforation can seal the indoor temperature, allowing room temperature to be maintained for some time.

4. Perforation can reduce weight. When two types of honeycomb panels with identical specifications are placed side by side on a perforation machine without perforation, the perforated panel weighs less than the non-perforated panel, which will significantly reduce the amount of work required for installation and use.

Naturally, perforation can effectively store heat, on the one hand, and can play the role of heat absorption, heat insulation, and heat preservation, on the other hand, it can make the foreign sound waves in the honeycomb structure repeatedly reflect, and constantly weaken until disappeared, having better absorption, sound insulation, and sound insulation function. Aluminum honeycomb panel with perforations. If you declare that you do not want to punch, you obviously cannot punch as you choose due to first or customer needs. Perforated aluminum honeycomb panels can be manufactured into curved panels, corner panels, and other shaped panels to satisfy the modeling needs of architectural ornamentation.

When buying perforated aluminum honeycomb panels, choosing a manufacturer to cooperate with is a more important part. How to choose a better-perforated aluminum honeycomb panel manufacturer is very important. Taking Julong as an example, you can judge whether the perforated aluminum honeycomb panel manufacturer is worth your long-term cooperation from many factors below.

Most buyers focus more on the quotation from the perforated aluminum honeycomb panel manufacturer when selecting a perforated aluminum honeycomb panel processor. When it comes to price, the more well-liked people are, the cheaper the price. However, such poor price competition worsens the market's price strategy. Numerous manufacturers are generating low-quality raw materials to cut costs, which has led to the phenomena of subpar products and numerous issues with engineering quality. That is a significant loss for unsophisticated buyers.

There are more factors to consider when picking a superior producer of perforated aluminum honeycomb panels. Julong provides you with a list of numerous important criteria, like product quality, delivery speed, affordability, engineering example experience, etc. Second, consider the manufacturer's overall strength, including factory offer, productivity (delivery cycle), production equipment, product quality, production capacity, production room scale, capital turnover capacity, project case experience, online and offline reputation, and other factors to assess the basis of manufacturer cooperation.

Although different perforated aluminum honeycomb panel producers have their distinctive qualities, smaller producers may also have some advantages. Since big brand manufacturers have no benefits in terms of scheduling, pricing, etc., it follows that small manufacturers' products have substantially lower quality and costs. Julong advises that you select the producers of perforated aluminum honeycomb panels. You may select a few producers to compare, and it's a good idea to be able to visit the factory workshop because it will make the experience more authentic.

The Intricate Process of Manufacturing Aluminum Composite Panels

Hyperboloid Solid Aluminum Sheet Innovation in Structural Design

Painting Hollow Aluminum Veneer Techniques and Tips for a Perfect Finish

Wood Aluminum Panel Fusion of Natural Warmth and Modern Strength

Stone Panel Aluminum Honeycomb Modern Marvel in Building Materials

Enhancing Architecture and Design with Color Coated Aluminum Coil