Views: 5 Author: Julong Publish Time: 2023-02-22 Origin: aluminum panel systems manufacturer

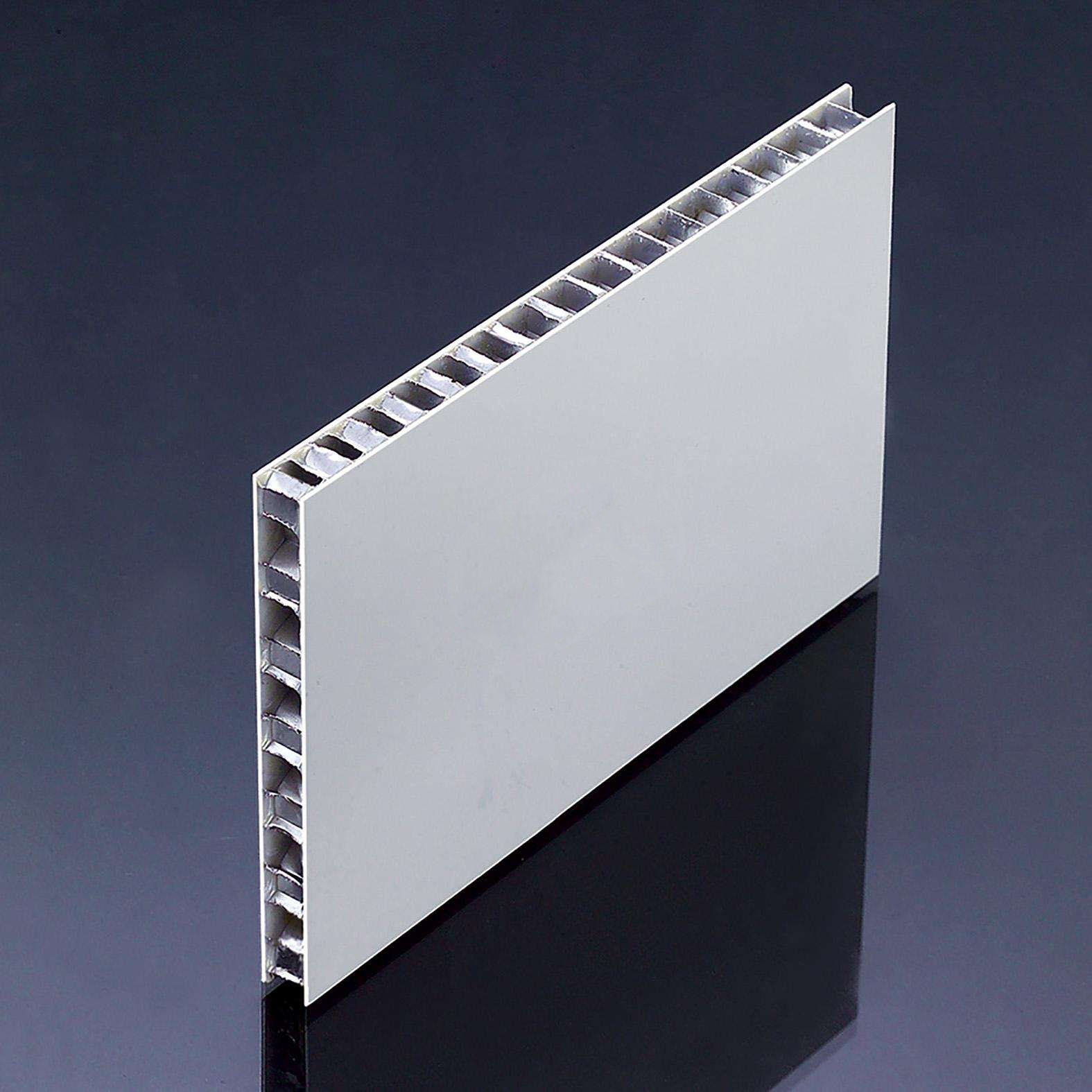

Aluminum honeycomb paneling is a popular interior and exterior building decoration material. It is primarily made up of an aluminum honeycomb core (type 3003, hexagonal), panel, and base plate (often made of pre-rolled aluminum) that are glued together at high temperature and pressure with aviation-grade adhesive. Honeycomb aluminum panels are not readily distorted, provide energy savings and environmental protection, provide sound insulation, are fire and moisture-resistant, and are simple to install, among other benefits. They are appropriate for exterior wall pinning, interior decorative projects, and other applications.

A honeycomb aluminum panel manufacturer's specification size is commonly represented as length x width, and the length is 1500mm, 2000mm, 2400mm, 3000mm, 3200mm, and so on. The widths are 1200 mm, 1250 mm, 1500 mm, etc. The thickness range is generally between 10 and 100 mm. If you have special needs, you can also directly contact the honeycomb aluminum sheet manufacturer to customize special shapes and special sizes of honeycomb aluminum sheet products. Honeycomb aluminum sheet may have a certain deviation in size during the production process, but it is generally within the allowed range. Today, this article introduces what sizes of aluminum honeycomb panels are available and what is the allowable deviation range of aluminum honeycomb panel size. I hope it will be helpful to you.

Honeycomb aluminum specification size table

As a new type of curtain wall decoration material, honeycomb aluminum panel has great market potential in the field of public decoration. The first consideration in the process of purchasing aluminum honeycomb panels is the selection of specifications, so do you know what the most popular sizes of aluminum honeycomb panels are?

Honeycomb aluminum plate is a type of environmentally friendly and energy-saving metal composite ornamental plate with a large specified size. The huge plate size of a honeycomb aluminum panel might be 4500x1500mm. the standard lengths of 1500mm, 2000mm, 2400mm, 3000mm, 3200mm, 4500mm, 5000mm, and so on. The standard widths are 1200 mm, 1250 mm, 1500 mm, and so on. Typically, the range is between 10 and 100 mm. The typical total thickness is 8 mm, 9 mm, 10 mm, 12 mm, 15 mm, 18 mm, 20 mm, 25 mm, 30 mm, 40 mm, and so on.

If you have special size and thickness requirements, you can also directly contact the honeycomb aluminum panel manufacturers for custom processing., The specific size can be determined according to the actual needs of customers.

Second, the aluminum honeycomb plate size allowable deviation range

General honeycomb aluminum panel manufacturers have a variety of specifications. In the actual production process, a certain amount of deviation is allowed, but not beyond a certain range. The conventional aluminum honeycomb plate size allowable deviation range is as follows:

1. Side length: not more than 2 m, with a size allowable deviation of no more than 2 mm, or more than 2 m, with a size allowable deviation of no more than 3 mm.

2. Thickness: ±0.25mm

3. Diagonal deviation: not more than 3mm

4. Side straightness: not more than 2mm/m

5. Flatness: not more than 2mm/m

a honeycomb: Of course, if your project is a shaped honeycomb aluminum sheet product, the allowable deviation range is generally agreed upon by both sides.

Third, the honeycomb aluminum plate purchase points

1. The thicker the honeycomb aluminum plate, the better the plate, and the current market circulation of honeycomb aluminum plate thickness is generally in the 7mm to 9mm range. Usually, the thicker the honeycomb aluminum plate, the stronger its resistance to deformation; the industry-standard thickness of a honeycomb aluminum plate is 9 mm.

2. For the choice of material, I suggest first choosing a high-quality plate. It is not easy to avoid bumps, pits, and other phenomena while ensuring that the surface of the plate is flat.

3. On the thickness of aluminum honeycomb core, such as the ceiling with aluminum honeycomb core, which is generally used as a side length 5-6mm honeycomb core, the denser the density, the more support points, and the flatter the plate.

The Intricate Process of Manufacturing Aluminum Composite Panels

Hyperboloid Solid Aluminum Sheet Innovation in Structural Design

Painting Hollow Aluminum Veneer Techniques and Tips for a Perfect Finish

Wood Aluminum Panel Fusion of Natural Warmth and Modern Strength

Stone Panel Aluminum Honeycomb Modern Marvel in Building Materials

Enhancing Architecture and Design with Color Coated Aluminum Coil