Views: 6 Author: Julong Publish Time: 2023-03-16 Origin: Site

The purpose of aluminum ceiling surface treatment is to protect the surface layer of aluminum from oxidation and keep it bright and colorful. There are multiple surface treatment processes; the most popular curved aluminum veneer has three: roller coating, spraying, and laminating. Roller-coated plates sprayed plates, and laminated plates are the three types of aluminum plates. This text primarily introduces the roller-coated plate's raw materials, procedure, advantages and disadvantages, and inspection standards.

1. Raw material and process

The roller coating method is as follows: the surface of the metal is covered with the paint specified by the customer, and following high-temperature baking, a coated aluminum coil is made. To achieve coating adhesion, i.e., adhesion, the metal must be cleaned before painting to make it easier to bond with the paint. Roller-coated panels are painted with four different types of paint: acrylic, polyester, fluorocarbon, and nanometer.

A. Acrylic is a kind of resisting paint (plastic), relatively hard, brittle, easy to dry, and cracks when bent; it is rarely used in high-level ceiling projects.

B. Polyester is a less dense plastic, with softness and strain when bending. Adding a polyurethane component to polyester can make it softer.

C. Fluorocarbon is a coating material made in the United States. Fluorine and carbon collection have better stability and will not change color in the case of wind, rain, and sunshine, which makes them excellent materials for outdoor projects.

D. Naomi is a new type of paint that was made by reducing the molecules of polyester and fluorocarbon to generate Naomi. It is distinguished by its brightness, self-cleaning ability, and lack of stickiness and dust. During construction, it is applied to a typically coated surface. Single, double, and triple coating methods are used in painting. A finished single coat of paint is referred to as a single coat. The primer is applied first, followed by the top coat in the double-coating process. Because the double coating has a thicker paint surface and better protection, the paint surface quality is better when bending. As a result, the double-coating method is commonly employed in high-level ceiling material. Triple coating means that on top of the first two layers, a layer of glossy paint is added.

2. Advantages and disadvantages of roller-coated board

Advantages: the paint is fine and smooth, like "apple skin." Paint and aluminum plate adhesion are good, and they use a relatively long period. It is impossible to replace the thickness of the aluminum plate with paint. because it is impossible to paint afterward. The use of paint to offset aluminum is not economical in terms of price.

Disadvantages: High requirements for aluminum; inferior aluminum cannot be painted. Some shaped plates of coated aluminum cannot be constructed. If the construction is carried out, the painted surface will be damaged and cannot be restored afterward.

3. Inspection index of a roller-coated board

Aluminum ceiling construction should make use of a good roller-coated board to provide proper ceiling suspension. The approval of roller-coated boards generally follows the aluminum composite industry-standard GB/T17748-1999. The quality, specification, and flatness of the painted aluminum substrate, among other things, should be checked during acceptance. It should also pay attention to the paint's quality. For example, there is no paint flaking after the product has been processed, and the surface is bright and clean, with no scratches, dents, color variances, paint leaks, spots, color bands, or other flaws. When the paint film thickness is 0.02 mm, the T-bend should be no more than 2T.

The color difference between the surface layer of the aluminum ceiling is also known as the color difference. If there is a color discrepancy, it will harm the construction quality. Even if the same equipment and technique are used in the manufacturing process but the items are created at various periods, the color will differ slightly. For example, if a project contains tens of thousands of square meters of ceiling panels, adopting the batch supply and batch production approach will result in the appearance of color discrepancies. When employing the recognition instrument, the color difference must now be E = 2, as specified in the GB/17748-1999 objective.

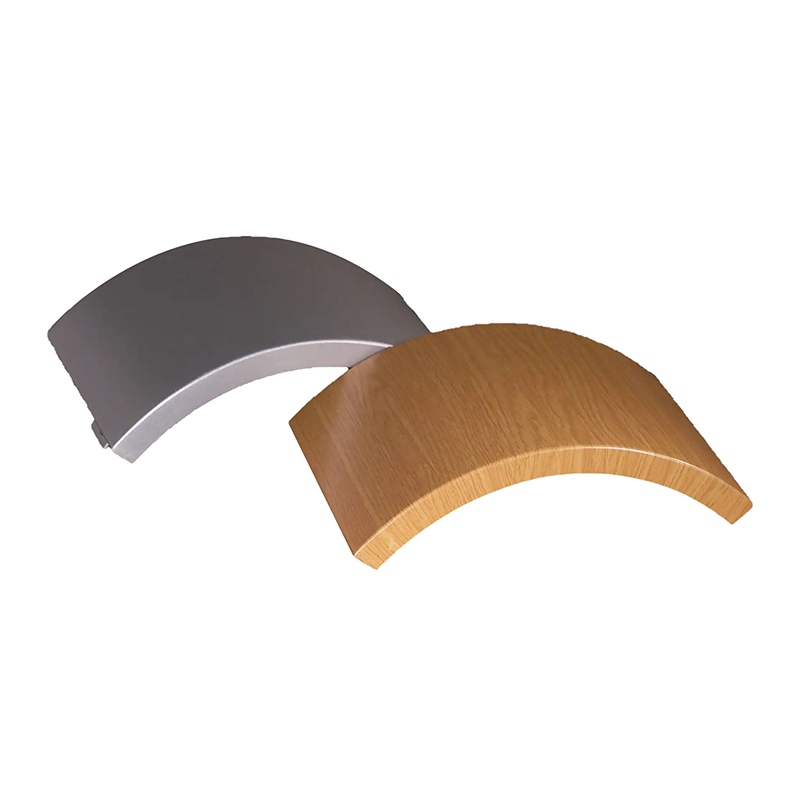

Please contact us if you require Single Curved Arc Modeling Aluminum Veneers.