Views: 2 Author: Julong Publish Time: 2023-03-17 Origin: aluminum panel systems manufacturer

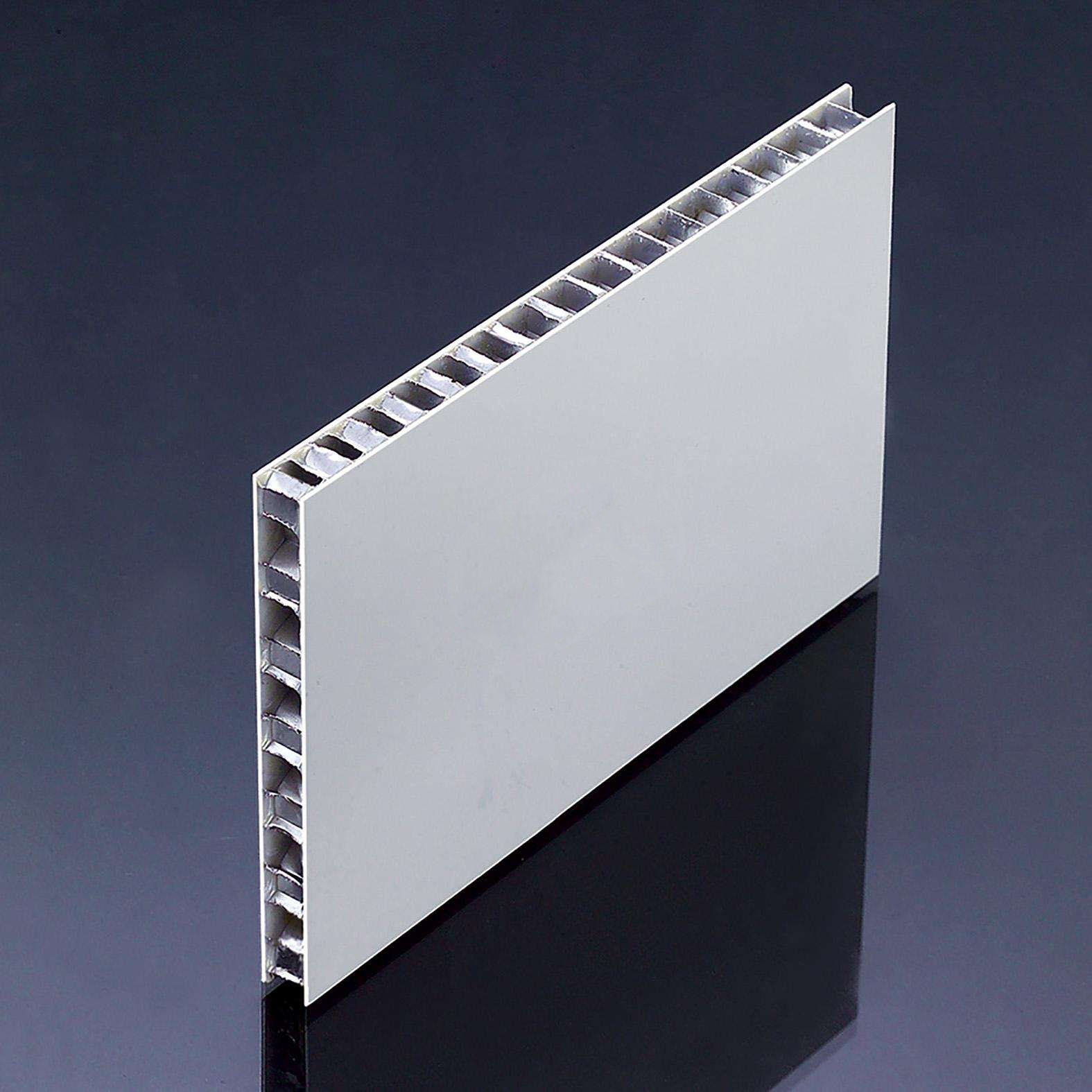

Aluminum veneer modeling can produce not only complicated double-curved designs, but aluminum honeycomb panels can also be made and processed into double-curved patterns. A hyperbolic aluminum honeycomb panel is made up of three parts: an aluminum alloy plate, an aluminum alloy base plate, and an aluminum honeycomb core material.

Numerous companies in the aluminum veneer manufacturing industry specialize in the production of aluminum honeycomb panels, but the difficulty of generating hyperbolic aluminum honeycomb panels is widely known. The production process of the panel and base plate on the sheet metal parts of the hyperbolic aluminum honeycomb panel is identical to that of the hyperbolic aluminum veneer. However, the installation in the middle and later stages should be completely considered, so the specifications' manufacture and processing accuracy should meet high technical standards. Precision in production and processing must be maintained to within 2 mm. If the accuracy deviation is relatively considerable, it will be extremely dangerous when installing the components later on.

Sheet metal processing culminates in the installation of an aluminum alloy plate, an aluminum honeycomb core, and an aluminum base plate. This entire process is known as "composite forming," and it is responsible for the "sandwich" structure of the aluminum honeycomb panels. However, the method of mold creation and processing is often chosen to ensure the quality of the hyperbolic aluminum honeycomb panels. The essential aspect influencing the quality of hyperbolic aluminum honeycomb panels is ensuring the accuracy of mold creation and processing. The compounding technology used in the fabrication of double-curved aluminum honeycomb panels will select a laminating agent based on the temperature of each component. Finally, at the bottom of the aluminum alloy panel surface of the composite aluminum panel, symmetrical scraping and deployment of a good symmetrical double set of the laminating agent are performed to add the honeycomb core material. The aluminum honeycomb core and aluminum alloy plate are then inserted within the mold by the aluminum panel. The following stage is to apply adhesive tape to the surface of the film, followed by vacuum pump charging while the adhesive dries.

As can be seen, the entire process of producing hyperbolic aluminum honeycomb panels is extremely difficult. If the customer has a different refractive index need for the hyperbolic aluminum honeycomb panel, it will be manufactured by a separate manufacturer of aluminum veneer or expenditure. As a result, the hyperbolic aluminum honeycomb panel is sharpening the company's technical level. Our company has many years of experience in manufacturing aluminum honeycomb panels; please contact us if you need to place an order.

Can I Install Aluminium Composite Panels Myself in Melbourne?

How To Make Aluminium Composite Panels: Industrial Process Explained

What Is The Aluminium Composite Panel Manufacturing Process?

How To Import Aluminium Composite Panels From UAE Manufacturers?

What Are The Leading Aluminium Composite Panel Brands in China?

Is Aluminium Composite Panel Weatherproof for Malaysia’s Climate?

Are Aluminium Composite Panel Kitchen Cabinets Worth The Investment?