Views: 3 Author: Julong Publish Time: 2023-03-13 Origin: aluminum panel systems manufacturer

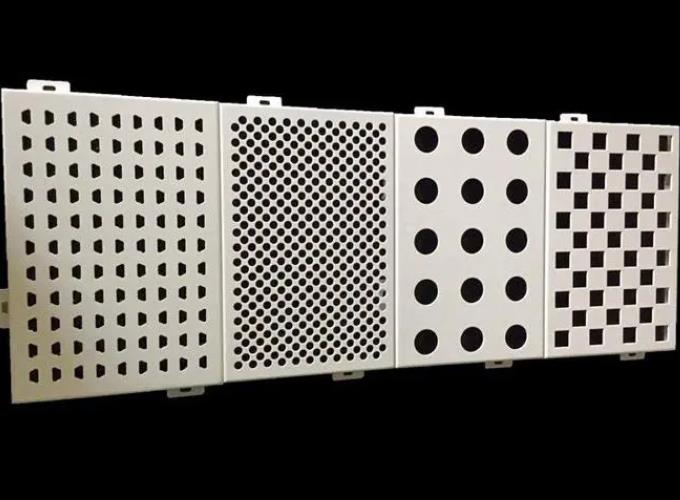

With the development of the economy, people's aesthetics have also been improved. The design of modern architecture shows the development trend of diversification. In the past, it was difficult for the building decoration materials to meet the designers' demand for personalized modeling, and the appearance of perforated aluminum veneer is very suitable for such a demand.

Perforated aluminum plate is made of the traditional flat aluminum plate in the sheet metal process according to the customer's custom requirements and the actual situation of the project, using a variety of CNC processing equipment to process various shapes of cavities, in the fluorocarbon paint or powder coating art caused by the aluminum plate. In addition to the benefits of standard aluminum sheets, perforated aluminum sheets provide a variety of perforation styles. Sound insulation can be absorbed by the filler on the back of the aluminum panel, making it perfect for conference centers. It is an excellent material for hotels and other commercial decorations. If it's used in building facades, wind can pass through the perforations, thus reducing wind resistance and increasing aesthetics.

The ten advantages of punched aluminum veneer are as follows.

1. Light weight, good rigidity, and high strength: 3.0mm perforated aluminum veneer weighs 8kg per square and has a tensile strength of 100-280N/mm.

2. Good craftsmanship: due to the process of processing first and then spraying, the aluminum plate can be customized into a flat. Curved or spherical and other complex shapes. Its process accuracy is high and does not damage the surface. The processing is cut under a cooling state, with no deformation. The cutting surface is smooth and burr-free, with a small cutting gap, which can adapt to various high-precision production.

3. Perforated aluminum veneer is specifically fireproof. Moisture-proof. Anti-corrosion and other advantages.

4. Weather resistance, corrosion resistance, UV resistance, and crack resistance of aluminum veneer. The service life of perforated aluminum veneer coated with fluorocarbon paint can reach 20 years without fading or deformation, with excellent performance.

5. Perforated aluminum veneer can be customized according to customer requirements, to meet the personalized modeling needs of different customers.

6. Perforated aluminum veneer is easy and fast to install and construct. An aluminum veneer is processed and shaped in the sheet metal workshop, no cutting is needed at the construction site, it only needs to be fixed on the skeleton, so the installation and maintenance are simple and flexible.

7. Aluminum veneer is not easy to stain and is conducive to cleaning and maintenance, the surface is difficult to adhere to pollutants, good self-cleaning.

8. Perforated aluminum veneer can significantly reduce noise.

9. Lightweight, strong plasticity, good durability. A perforated aluminum veneer can be recycled to be 100%, green and environmental protection.

10. Perforated aluminum veneer is durable, has quality assurance, warranty for more than 15 years.

In summary, the many advantages of perforated aluminum veneer have been widely used in exterior wall decoration and indoor high-grade decoration project ceilings and walls, with strong decorative performance. It is also suitable for exterior wall decoration of large buildings, multifunctional restaurants, lecture halls, opera houses, reception halls, concert halls, hotels, and leisure and entertainment places.

Hot Tags: Aluminum veneer, Perforated aluminum veneer, punched aluminum veneer, aluminum veneer manufacturer, aluminum panels, Aluminum composite panels

Can Atap Aluminium Composite Panels Withstand Extreme Weather Conditions?

How Durable Are Aluminium Composite Panels in Harsh Weather?

How Can Alustar Aluminium Composite Panels Enhance The Aesthetic of Your Building?

What Factors Affect The Weight of Aluminum Composite Panels Per Square Meter?

How Long Do Aluminum Composite Panels Last in UAE's Harsh Climate?

What Are The Most Effective Tools for Drilling Aluminum Composite Panels?

What Is The Cost of Aluminum Composite Panels From Suppliers in Canada?