Views: 201 Author: Julong Publish Time: 2023-05-18 Origin: aluminum panel systems manufacturer

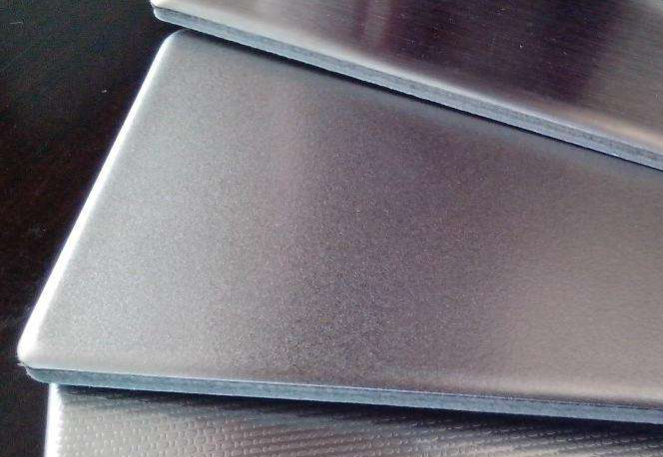

A metal composite panel is a composite material made of metallurgically bonding metals with varying characteristics at the interface using various composite technologies. The metal composite panel can greatly improve the thermal expansion, strength, toughness, wear resistance, corrosion resistance, electrical properties, magnetic properties, and many other properties of a single metal material through appropriate material selection and reasonable structural design and is thus widely used in petroleum, chemical, shipping, metallurgy, electric power, water conservancy, transportation, environmental protection, food, pharmaceutical, and ophthalmic industries. Metal composite panels, in addition to their structural and functional properties, can conserve precious metals and drastically lower the cost of various equipment materials.

Metal composite material technology can bring the respective advantages of the component materials into play and realize the optimal use of each component material's resources. Furthermore, it can preserve precious metal materials while meeting performance criteria that cannot be met by a single metal. For a pressure vessel with a stainless steel-steel composite plate, for example, the general carbon steel base (Q245R, Q345R, etc.) has very good mechanical qualities, and the stainless steel composite layer (304, 316L, etc.) has very good corrosion resistance.

The two are often blast welded together, needing only a few millimeters of high-priced stainless steel, which saves money and has no effect on the various mechanical qualities of the base material. It can replace imports and fill domestic gaps, but it also offers a wide range of uses, good economic and social benefits, and simple access to all forms of support and assistance. For example, the National Development and Reform Commission and the Ministry of Science and Technology will actively encourage and advocate for high-tech projects, such as the development of stainless steel composite materials. (Stainless Steel Composite Sheet)

As the performance of heterogeneous metal composites improves, the development potential of traditional metal composites increases due to functionalization, a lower cost, and a wide range of applications. The use of rare metal composites in power flue gas desulfurization equipment is becoming more common as the national environmental protection industry policy is strengthened. Simultaneously, the localization of investment in the chemical industry has quickened, providing good development potential for the development of rare metal materials.

The backing of national industrial policy, higher technical barriers, and the demand-pull of industrial upgrading open up a large area for industry expansion. A metal composite panel is a metal layer overlaid with another metal plate that has the effect of conserving resources and lowering prices while maintaining the usage effect (anti-corrosion performance, mechanical strength, and so on).