Views: 325 Author: Julong Publish Time: 2023-11-03 Origin: aluminum panel systems manufacturer

Because of their superior performance and attractive appearance, aluminum honeycomb panels are widely used in the aluminum furniture industry. They are used in the manufacture of cabinets, chairs, and tables, as well as custom furniture designs.

Aluminum honeycomb panels are strong, light, stiff, and long-lasting. A honeycomb's cellular structure provides excellent strength-to-weight ratios and superior rigidity. Significant weight savings are possible in complex and large-scale furniture designs, resulting in increased efficiency and lower production costs. The honeycomb structure eliminates the need for additional support structures, resulting in a more visually appealing design. Furthermore, Aluminum Honeycomb Panels have superior corrosion resistance and fire performance. They are ideal for environments requiring fire protection due to their non-combustible core material and non-flaming surface coating. Aluminum honeycomb panels are also resistant to moisture, fungi, and insects, and will not warp, crack, or delaminate.

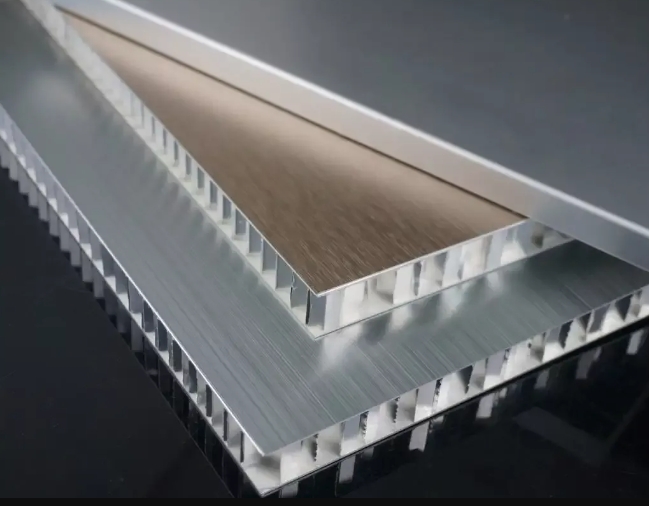

The aluminum honeycomb panel is composed of two aluminum face sheets joined together by an aluminum honeycomb core. Aluminum has a fire rating of A and is therefore non-combustible. The surface of the aluminum honeycomb panel has been treated with a corrosion-resistant coating. Aluminum honeycomb panels emit no harmful gases into the environment, are non-radioactive, and can be completely recycled. It is simple to disassemble, simple to assemble, heavy, portable, and can be reused numerous times. Reduce the construction load significantly.

The middle aluminum honeycomb contains a large amount of air that is both sound and heat-insulated. Moisture-proof, with no harmful gases emitted. It is an excellent material for applications requiring light weight and high strength, and it is not easily deformed. which eliminates the drawbacks of other decorative panels, such as deformation and intermediate collapse when the single-piece area is large. It is simple to work with and can be cut and folded in workshops.

The surface is extremely flat and has good seismic performance. Fluorocarbon roll-coated skin sheets are commonly used in aluminum honeycomb panels. The painting is completed all at once, with minor color variations, good coating leveling, and consistent quality. It can keep the building's outer wall brightly colored for a long time. It is clean and bright, can withstand long-term sun and rain exposure, and has good adhesion and weather resistance.

Aluminum honeycomb panels can be used for curtain wall exterior cladding, interior decoration projects, billboards, shipbuilding, aviation manufacturing, indoor partitions, commodity display stands, commercialization vehicles, container bodies and truck bodies, buses, trains, subways, and tracks traffic vehicles due to the benefits listed above.

Aluminum Honeycomb Panels are an excellent choice for use in the aluminum furniture industry due to their superior strength and aesthetic appeal. They provide a lightweight, low-cost solution that is both durable and aesthetically pleasing.

In recent years, there has been a significant increase in the adoption of innovative materials for creating functional and aesthetically pleasing designs in the home decor market. Aluminum honeycomb core has emerged as a game changer among these materials, particularly in the realm of invisible doors. In this article, we will look at the reasons for the increasing popularity of aluminum honeycomb core and its applications in invisible doors, which are changing the way we design and experience modern living spaces.

A lightweight and highly versatile material composed of hexagonal cells sandwiched between thin aluminum sheets, aluminum honeycomb core is a lightweight and highly versatile material. Because of its unique structure, it has a remarkable strength-to-weight ratio, making it ideal for a wide range of applications across industries. One of the main reasons for its popularity in the home decor market is its ability to provide exceptional structural integrity while remaining lightweight.

Invisible doors, also known as concealed doors or hidden doors, have emerged as a popular option for modern interior design. These doors blend in with the surrounding walls, giving the living space a sleek and minimalist appearance that adds to the overall aesthetic appeal. Homeowners and interior designers alike are drawn to this trend because of its ability to maximize available space while also adding an element of surprise and sophistication.

3.1 Lightweight and Easy to Handle: The lightweight properties of the aluminum honeycomb core make it easier to handle during installation, reducing the need for heavy-duty hardware and allowing for the hassle-free installation of invisible doors.

3.2 Strength and Durability: Despite its lightweight, the aluminum honeycomb core is extremely strong and durable, ensuring that invisible doors retain their integrity over time and withstand regular use.

3.3 Improved Acoustic and Thermal Insulation: The hexagonal cells in the honeycomb core create air pockets that contribute to improved acoustic and thermal insulation, making invisible doors with this core ideal for maintaining a comfortable and quiet indoor environment.

3.4 Design Versatility: The adaptability of the aluminum honeycomb core enables designers to create unique invisible doors that match various interior themes, including customization of sizes and shapes.

4.1 Residential Areas In residential settings, where space optimization and aesthetic appeal are important, invisible doors with aluminum honeycomb cores are extremely useful. These doors can be integrated seamlessly into living rooms, bedrooms, and walk-in closets, adding a touch of elegance to modern homes.

4.2 Commercial Spaces: Invisible doors with aluminum honeycomb cores contribute to a sophisticated and professional ambiance in commercial settings such as offices, hotels, and retail stores. They are an excellent choice for dividing meeting rooms, private cabins, and storage spaces due to their space-saving features and sleek appearance.

As the home decor market evolves, the use of aluminum honeycomb cores in the design of invisible doors has become a significant trend. The aluminum honeycomb core is an ideal material for creating doors that blend seamlessly into modern living spaces due to its lightweight, durable, and versatile properties. The aluminum honeycomb core elevates the concept of invisible doors with its improved acoustic and thermal insulation, providing not only aesthetic but also functional benefits for homeowners and commercial spaces alike. Aluminum honeycomb core is set to maintain its position as a top choice for the future of home decor and interior design as demand for innovative and space-saving design solutions grows.