Views: 201 Author: Julong Publish Time: 2023-06-06 Origin: aluminum panel systems manufacturer

Aluminum honeycomb panels have been a popular choice in the home furnishings sector in recent years. It has gradually gained popularity among users due to its smooth surface and great flatness. However, as technology advances, the widespread use of honeycomb panels has become one of the primary manufacturers' worries. This essay will mostly introduce you to aluminum honeycomb panels.

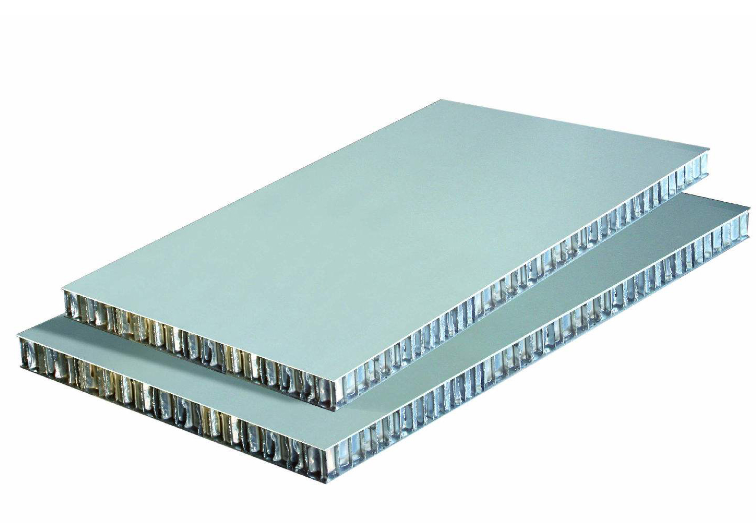

The hexagonal honeycomb with an aluminum honeycomb core is considered a natural miracle. It has a stronger construction than any round or square structure and can bear external forces from all directions. Because of the honeycomb's unique structure, humans were inspired. As long as it is constructed of aluminum and honeycomb, even the thinnest material can bear significant external forces, is not easily bent, is stable, can be recycled, and is healthier and environmentally beneficial.

The honeycomb sandwich structure is a special kind of composite material. Since this lightweight structural material has the best specific strength, specific stiffness, maximum fatigue resistance, and smooth surface, it was first developed as an ultra-lightweight composite material to meet the special needs of aerospace science and technology.

Click here for Honeycomb Panels for Sale.

The honeycomb aluminum skin features small perforations to allow unrestricted gas movement within the panel; the system causes minimal structural distortion during thermal expansion and cold contraction. The panel is mostly constructed using high-quality aluminum alloy aluminum plates or Gaumeng alloy aluminum plates as the substrate, as well as roller-coated plates or other industrial plates. If there are strong requirements for scratch resistance, acid rain corrosion discoloration, and self-cleaning in areas and locales, the specific anti-corrosive surface coating and hexagonal aluminum honeycomb core can be selected.

The honeycomb panel is manufactured entirely in a contemporary factory. The pressing process is heated. The thermal expansion and cold contraction of the inner and outer aluminum panels are synchronized due to the high thermal conductivity value between the aluminum and honeycomb; there are holes in the honeycomb aluminum shell, which means that the gas inside the panels can flow freely; the two-component polyurethane high-temperature curing adhesive uses automatic honeycomb panel lamination production equipment, which overcomes the brittleness of the previous honeycomb p The inner layer consists of an aluminum alloy hexagonal honeycomb core. Tangential pressure is applied to a core panel that is adhered to the sandwich construction. As with many small I-beams, these densely bound honeycombs disperse and withstand the pressure in the direction of the panel, subjecting the honeycomb panel to uniform stresses to ensure that the panel remains highly flat over a large area.

The honeycomb panels' center is an aluminum hexagonal honeycomb. The honeycomb cores are connected in the same way as I-beams are. The core layers are dispersed and fixed across the whole surface of the board, making it more robust and resistant to bending and compression. It has a substantially higher wind resistance than aluminum-plastic panels and aluminum veneers, and it is not easily bent. Even if the honeycomb panel is vast in size, it may achieve great straightness. Because the honeycomb core of the honeycomb composite panel is separated into several closed chambers, airflow is blocked and heat and sound waves are considerably reduced. Therefore, it has thermal, thermal, and acoustic insulation effects. Honeycomb panel is a pure aluminum product that does not evaporate any harmful gases, is non-radioactive, and can be fully recycled. It is a 100% environmentally friendly product.

Aluminum honeycomb panel has become a very popular two-way health and environmental protection material in the market since its creation. Meanwhile, with the advancement of domestic manufacturing technology, aluminum honeycomb panels are becoming increasingly popular. Artistic materials of diverse shapes, colors, and structures are increasingly being employed in space, and have become a popular trend in house-building material decoration.