Views: 222 Author: Robert Publish Time: 2024-12-05 Origin: Site

Content Menu

● What Are Durabond Aluminum Composite Panels?

● Key Benefits of Durabond Aluminum Composite Panels

● Applications of Durabond Aluminum Composite Panels

● Comparing Durabond ACPs to Other Materials

● Maintenance Tips for Longevity

>> 1. What are the main advantages of using Durabond aluminum composite panels?

>> 2. How long do Durabond aluminum composite panels last?

>> 3. Can Durabond ACPs be recycled?

>> 4. Are there specific installation methods recommended for Durabond ACPs?

>> 5. How do I clean my Durabond aluminum composite panels?

Durabond Aluminum Composite Panels (ACPs) have gained significant popularity in the construction and design industry due to their unique combination of durability, aesthetic appeal, and versatility. This article delves into the durability of Durabond aluminum composite panels, exploring their composition, benefits, applications, maintenance requirements, and more.

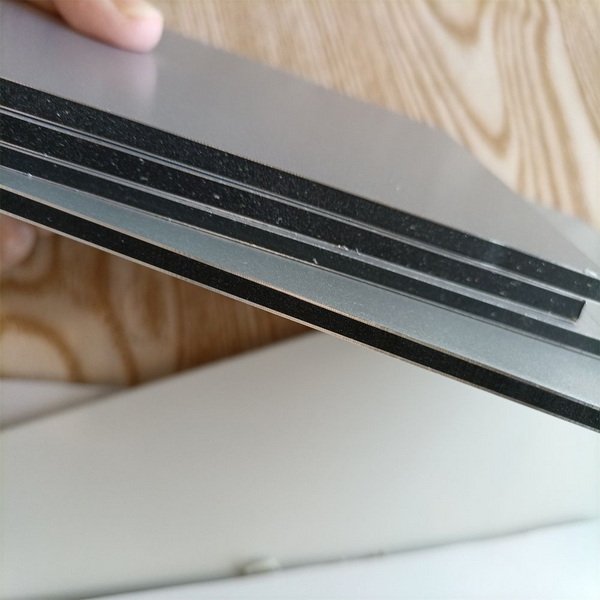

Durabond aluminum composite panels are engineered materials made up of two thin layers of aluminum enclosing a non-aluminum core. This composite structure provides a lightweight yet robust solution for various architectural applications. The outer aluminum sheets are typically coated with a protective layer that enhances resistance to weathering and corrosion.

The standard composition of Durabond ACPs includes:

- Two Aluminum Sheets: These sheets provide structural integrity and are often coated with a high-quality finish for aesthetics and protection.

- Core Material: The core can be made from materials such as polyethylene (PE) or fire-resistant (FR) materials, depending on the specific application requirements.

This sandwich construction results in panels that are not only lightweight but also exceptionally strong, making them suitable for various environmental conditions.

1. Durability: Durabond ACPs are designed to withstand harsh weather conditions, including UV exposure, rain, and temperature fluctuations. They are resistant to corrosion and do not warp or crack under extreme conditions.

2. Low Maintenance: The protective coatings on Durabond panels require minimal upkeep. Regular cleaning with mild soap and water is often sufficient to maintain their appearance.

3. Fire Resistance: Many Durabond panels come with fire-resistant cores, making them compliant with safety regulations in commercial buildings.

4. Aesthetic Versatility: Available in a wide range of colors and finishes, Durabond ACPs can mimic natural materials like wood or stone, allowing for creative architectural designs.

5. Sound Insulation: The composite structure provides effective sound insulation, making them ideal for urban environments where noise reduction is essential.

6. Eco-Friendly Options: Some Durabond panels are manufactured using recycled materials and are themselves recyclable at the end of their life cycle, contributing to sustainability efforts in construction.

Durabond aluminum composite panels are used in various applications, including:

- Building Facades: Their durability and aesthetic appeal make them a popular choice for exterior cladding in both residential and commercial buildings.

- Interior Decoration: ACPs can be used for wall partitions, ceilings, and decorative elements within buildings.

- Signage: Due to their lightweight nature and ease of customization, they are frequently used for outdoor signage.

- Renovations: The versatility of Durabond panels allows them to be easily integrated into existing structures during renovations.

- Transportation Industry: They are increasingly utilized in the transportation sector for vehicle interiors and exteriors due to their lightweight properties which contribute to fuel efficiency.

- Retail Spaces: Retail environments benefit from the aesthetic flexibility of Durabond ACPs, allowing businesses to create eye-catching displays and signage that attract customers.

To understand the advantages of Durabond aluminum composite panels better, it's helpful to compare them with other common building materials:

| Feature | Durabond ACPs | Solid Aluminum | Wood | Vinyl |

|---|---|---|---|---|

| Weight | Lightweight | Heavier | Moderate | Lightweight |

| Corrosion Resistance | High | Moderate | Low | Moderate |

| Maintenance | Low | Moderate | High | Low |

| Fire Resistance | High (with FR core) | Moderate | Low | Low |

| Aesthetic Options | Extensive | Limited | Limited | Moderate |

| Cost | Competitive | Higher | Variable | Lower |

The installation of Durabond aluminum composite panels is straightforward due to their lightweight nature. Here's a brief overview of the installation process:

1. Preparation: Ensure the surface where the panels will be installed is clean and free from debris. This step is crucial for ensuring proper adhesion or fastening.

2. Cutting: Panels can be cut using standard tools such as utility knives or saws designed for aluminum cutting. Accurate measurements are essential to avoid waste and ensure a perfect fit.

3. Mounting: Panels can be mounted using mechanical fasteners or adhesive bonding methods depending on the design requirements. It is important to follow manufacturer guidelines regarding spacing and fastening techniques to ensure structural integrity.

4. Finishing Touches: After installation, any necessary trims or seals should be applied to enhance durability and aesthetics. This may include edge trims or caulking to prevent moisture ingress.

To ensure the longevity of Durabond aluminum composite panels:

- Regularly clean the surface with mild soap and water to remove dirt and grime. Avoid harsh chemicals that could damage the finish.

- Inspect for any signs of damage or wear periodically. Early detection of issues can prevent more significant problems down the line.

- Avoid using abrasive cleaners or tools that may scratch the surface finish. Instead, opt for soft cloths or sponges during cleaning.

- Ensure that any sealants used around edges remain intact to prevent moisture penetration which could lead to deterioration over time.

Durabond aluminum composite panels also have an environmental aspect worth considering:

- Sustainability: The manufacturing process has evolved to include sustainable practices such as using recycled materials in production. This not only reduces waste but also lowers the carbon footprint associated with new material production.

- Energy Efficiency: The insulation properties of ACPs contribute positively towards energy efficiency in buildings by reducing heating and cooling costs over time.

- End-of-Life Recycling: At the end of their lifespan, Durabond panels can be recycled effectively, further minimizing environmental impact compared to other non-recyclable materials.

When evaluating whether to use Durabond aluminum composite panels in a project, cost is an important factor:

- Initial costs may be higher than some traditional materials; however, considering their longevity and low maintenance needs can result in lower overall lifetime costs.

- The competitive pricing compared to solid aluminum makes them an attractive option for many builders looking for cost-effective solutions without compromising quality or aesthetics.

In summary, Durabond aluminum composite panels offer exceptional durability along with aesthetic versatility, making them an ideal choice for modern architecture. Their lightweight nature allows for easy installation while providing long-lasting performance in various environmental conditions. With minimal maintenance requirements and extensive applications ranging from building facades to interior decor, Durabond ACPs stand out as a reliable building material in today's construction industry. Their eco-friendly options further enhance their appeal as sustainable choices in modern construction practices.

Durabond ACPs provide durability, low maintenance needs, fire resistance (especially those with FR cores), aesthetic versatility, sound insulation properties, and eco-friendly options through recycling initiatives.

With proper care and maintenance, Durabond panels can last up to 50 years or more without significant degradation in performance or appearance due to their robust construction and protective coatings.

Yes, aluminum composite panels are recyclable at the end of their life cycle. Many manufacturers have programs in place that facilitate recycling efforts as part of sustainable building practices.

Installation methods can vary but generally include mechanical fastening or adhesive bonding based on project requirements. It is essential to follow manufacturer guidelines during installation to ensure optimal performance and safety standards are met.

Cleaning can be done easily using mild soap and water with a soft cloth or sponge. Avoid harsh chemicals or abrasive materials that could damage the panel's surface finish; regular cleaning helps maintain their appearance over time.

Are Aluminum Composite Panels Weather-Resistant in Singapore’s Climate?

Is Aluminum Composite Panel Section Waterproof And Fire Resistant?

Is Aluminium Composite Panel Wall Cladding Worth The Investment?

Are Aluminium Composite Panels Weatherproof in The UK Climate?

Can You Import Aluminium Composite Panel Textures into SketchUp Easily?