Views: 202 Author: Julong Publish Time: 2023-06-13 Origin: aluminum panel systems manufacturer

Generally speaking, the higher the surface density of the panels, the better the sound insulation effect will be, but the pursuit of high surface density will also bring an increase in cost and raise the difficulty of transportation and loading costs. In the selection of wall and zoning materials for industrial plants, high-rise buildings, public facilities, etc., traditional clay walls, which have disadvantages such as high self-weight and large occupation areas, are gradually being replaced by new lightweight composite walls.

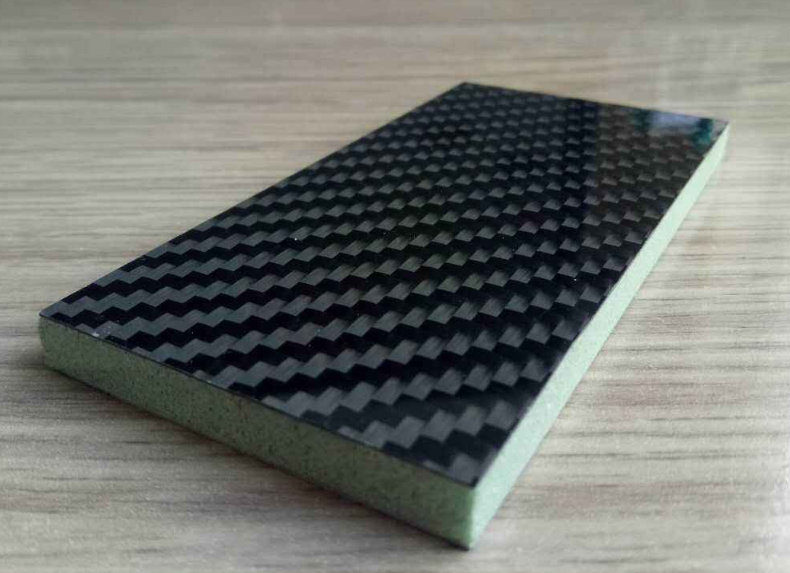

In general, the sound insulation of a brick wall with a thickness of 24cm is around 40dB, whereas the average sound insulation of a lightweight wall with a surface density of 20kg/m2 is just 30dB, which is far from adequate. The sandwich construction has now become one of the most effective lightweight sound insulation solutions for overcoming the contradiction between light mass and high sound insulation. As a particular composite structure, carbon fiber honeycomb sandwich structure has the benefits of light mass, high strength, heat insulation, and sound insulation, and has been widely used in many fields such as aerospace, aviation, rail transportation, and building.

Carbon fiber aluminum honeycomb sandwich panelstructures are increasingly used in the aerospace industry, high-speed trains, and automobile structures. To study its sound insulation performance which has an important influence on the noise in the vehicle and cabin, researchers have established a finite element model of the carbon fiber aluminum honeycomb sandwich structure and studied the effects of carbon fiber panel thickness, number of panel layers, lay-up angle, as well as the thickness of the aluminum honeycomb core layer and the thickness of the aluminum honeycomb on the sound insulation performance.

When sound is transmitted through the honeycomb panel structure to the honeycomb panel walls, it will vibrate back and forth within each small honeycomb, which is equivalent to adding multiple layers of sound insulation, and the consumption of sound energy will be relatively large. At the same time, for specific frequencies of sound waves, the honeycomb structure can prevent the sound waves from continuing to propagate, thus being able to achieve good noise reduction effects.

When the panel adopts carbon fiber composite structure, in the low frequency band less than 1000 Hz, the sound insulation performance of aluminum honeycomb composite structure with the same panel thickness is lower than that of aluminum honeycomb sandwich composite structure with all aluminum alloy material, and the sound insulation trough with lower sound insulation amount will appear in the high frequency band; compared with aluminum alloy panel, the addition of carbon fiber composite panel can not only realize the overall structural lightweight, but also improve the sound insulation performance of the composite structure; the best sound insulation performance of the composite structure when the layers are laid at 90° relative to each other; the sound insulation performance of the composite structure increases with the increase of the panel thickness, and the sound insulation performance of the composite structure will be reduced by a single panel or too many layers when the total thickness of the panel layer remains unchanged.

Is Aluminium Composite Panel Wall Cladding Worth The Investment?

Are Aluminium Composite Panels Weatherproof in The UK Climate?

Can You Import Aluminium Composite Panel Textures into SketchUp Easily?

How To Get The Lowest Aluminum Composite Panel Price in The Philippines?

Is Aluminum Composite Panel Affordable in The Philippines in 2025?

What Is The Current Aluminum Composite Panel Price in Pakistan?

What Is The Current Aluminum Composite Panel Price in India?

How To Install Aluminum Composite Panels in The Philippines?