Views: 221 Author: Site Editor Publish Time: 2023-04-14 Origin: Site

Only strict raw material control allows for the production of high-quality products. Because carved aluminum veneer is made of aluminum alloy, you must first select the raw material for the aluminum veneer if you want to produce high-quality aluminum veneer products. So, how do you evaluate the carved aluminum veneer material's quality? Click here to visit our collection of aluminum plastic composite panel.

This is mainly through the observation of the surface of the aluminum veneer material and hand touch.

1. The text on the surface of aluminum veneer material is generally printed with imported spray code, clear handwriting, trademark logo, manufacturer, telephone address, and other clear and true labels; counterfeit and shoddy aluminum veneer material surface text printed by ordinary printing machines, fuzzy handwriting, its manufacturer, and logo are generally unknown or not marked.

2. aluminum veneer material uses high-quality raw materials, its processing is precise, and the surface and inner layer feel smooth and free of mottling, and aluminum pipe is of poor quality because of jerry-building and relatively poor production.

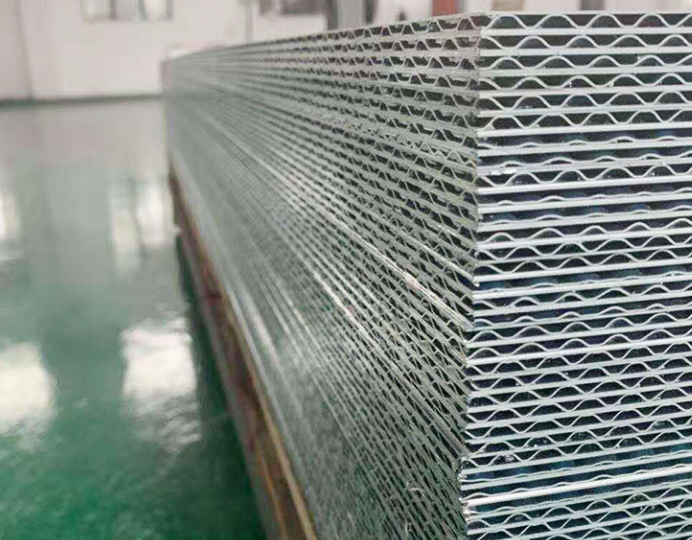

3. Aluminum-plastic pipe mouths and aluminum strip wall thickness uniform, aluminum veneer material combine closely. Tube and aluminum strip quality and thickness are in line with the relevant domestic standards; inferior products' wall thickness deviation is large, aluminum is thin, and the aluminum veneer material gap is large.

To fire the tube, use an open flame. Real aluminum-plastic tubing is produced via ultrasonic lap or butt welding using hydrogen arc welding. The interface is tighter, and the aluminum plate is less likely to slide off after the open flame burns the pipe. Because the aluminum plate on the counterfeit and shoddy aluminum-plastic pipe and other composite pipes is not welded, the interface is not closed, and the aluminum plate will break off after lighting.

Use pipe shears to cut aluminum veneer material into strips according to the spiral shape, and manually peel the aluminum veneer material layer and PE layer. The real aluminum plastic tube is a 5-layer composite structure with an aluminum layer and a PE layer that are closely combined. The aluminum veneer material layer and the PE layer are not easy to separate by hand. And crude products due to jerry-building, the aluminum layer, and the PE layer are not close, easy to peel off.

Using a tiny pressure pump, test the pressure capability of the aluminum veneer material. Real aluminum plastic pipe has a high bursting pressure that can meet or surpass the requirements of relevant domestic regulations. Inferior items in the pressure bursting are often low to low, making it difficult to meet the criteria of use.

Is Aluminium Composite Panel Wall Cladding Worth The Investment?

Are Aluminium Composite Panels Weatherproof in The UK Climate?

Can You Import Aluminium Composite Panel Textures into SketchUp Easily?

How To Get The Lowest Aluminum Composite Panel Price in The Philippines?

Is Aluminum Composite Panel Affordable in The Philippines in 2025?

What Is The Current Aluminum Composite Panel Price in Pakistan?

What Is The Current Aluminum Composite Panel Price in India?

How To Install Aluminum Composite Panels in The Philippines?