Views: 201 Author: Julong Publish Time: 2023-08-22 Origin: Site

Although the customized production of aluminum veneer has a broad market prospect, but also faces some challenges, and need to overcome some process and technical difficulties. In this paper, we will discuss the challenges faced by the customized production of aluminum veneer and the related process and technical difficulties.

With the increasing demand for architectural appearance and details, the demand for customized aluminum veneer has become more diverse. This means that manufacturers need to personalize their products according to different projects and customer requirements, including size, color, shape and other aspects of customization. This brings challenges for producers, such as how to provide diversified choices and meet the various needs of customers. At the same time, manufacturers also need to keep track of market trends and update their designs and technologies to meet changing market demands. Related product: Aluminum Veneer Sheets.

Aluminum veneer in the custom production process needs to work closely with the design team to ensure the feasibility and consistency of the design. The synergy between design and process is one of the key difficulties in customized production. Producers need to understand the designer's design intent and translate it into an implementable process. However, there may be issues where the design cannot be realized in the process, such as limitations in size, shape, etc. Therefore, the producer needs to actively communicate and cooperate with the designer to find the best solution.

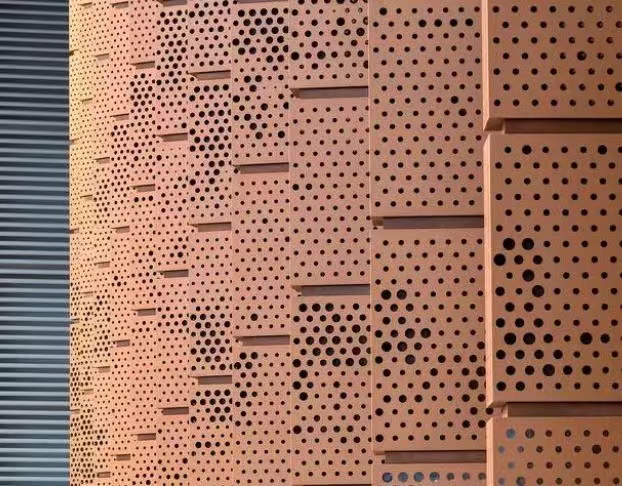

Customized production of aluminum veneer involves many process technologies, including cutting, bending, welding, punching and so on. The accuracy and stability of these processes are critical to the quality and appearance of the final product. Among them, bending technology is one of the more critical process challenges. The bending of aluminum veneer needs to take into account factors such as the mechanical properties of the material, thickness and angle to ensure the accuracy and reliability of the bending. In this process, it is necessary to use professional equipment and processes, and fine control and adjustment to ensure the accuracy and consistency of bending.

Material selection is an important part of the custom aluminum veneer production process. Different projects and needs require different performance and appearance of materials. Therefore, producers need to understand the characteristics, advantages and disadvantages of various materials and choose the most suitable materials. In addition, quality inspection and testing of materials are also very important to ensure that the quality and performance of the products meet the standards.

Although the customized production of aluminum veneer faces some challenges, with the advancement of technology and market demand, manufacturers can continue to improve the production level and quality to meet the diversified market demand by strengthening the collaboration with the design team, optimizing the process, and introducing advanced equipment and technology. At the same time, the production of customized aluminum veneer also provides more innovative and personalized design options for the construction industry, promoting the development and progress of the industry.

Is Aluminium Composite Panel Wall Cladding Worth The Investment?

Are Aluminium Composite Panels Weatherproof in The UK Climate?

Can You Import Aluminium Composite Panel Textures into SketchUp Easily?

How To Get The Lowest Aluminum Composite Panel Price in The Philippines?

Is Aluminum Composite Panel Affordable in The Philippines in 2025?

What Is The Current Aluminum Composite Panel Price in Pakistan?

What Is The Current Aluminum Composite Panel Price in India?

How To Install Aluminum Composite Panels in The Philippines?