Views: 224 Author: Robert Publish Time: 2024-11-18 Origin: Site

Content Menu

● Introduction to Aluminum Honeycomb Panels

>> Applications in Construction

>> Applications in Transportation

>> Applications in Electronics

● Advantages of Aluminum Honeycomb Panels

>> 1. What are aluminum honeycomb panels made of?

>> 2. Why are aluminum honeycomb panels used in aerospace?

>> 3. Can aluminum honeycomb panels be used in marine applications?

>> 4. What advantages do aluminum honeycomb panels offer in construction?

>> 5. How do aluminum honeycomb panels contribute to energy efficiency?

Aluminum honeycomb structural panels have gained significant traction across various industries due to their unique properties, including lightweight construction, high strength-to-weight ratio, and excellent thermal and acoustic insulation. This article explores the diverse applications of aluminum honeycomb panels, highlighting the industries that benefit most from their use.

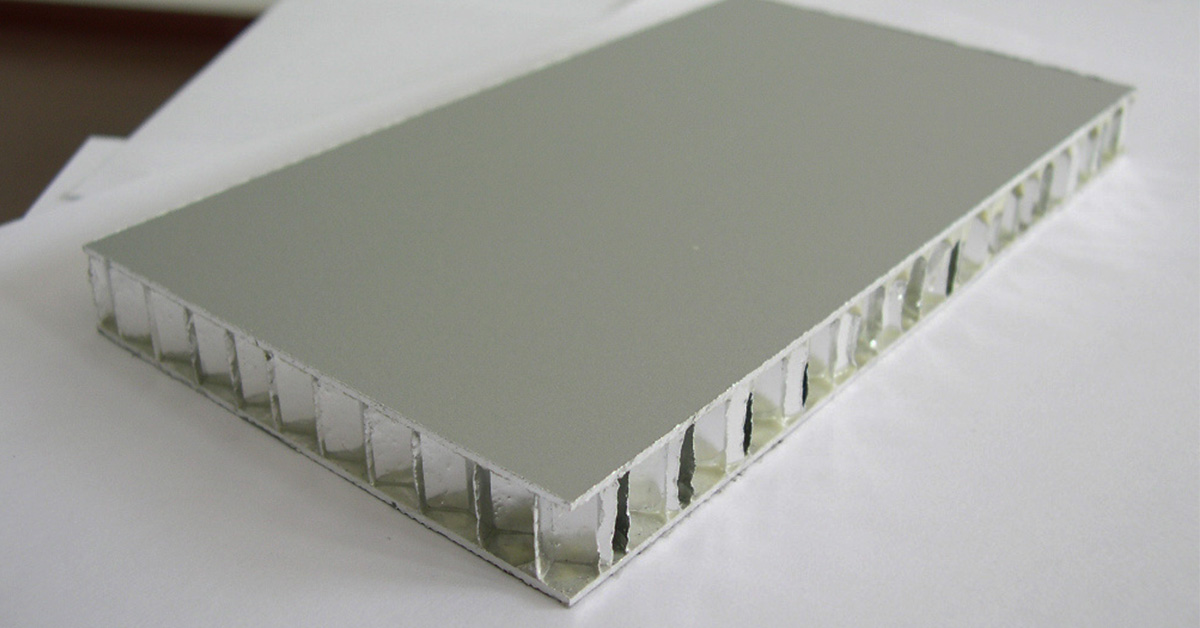

Aluminum honeycomb panels consist of two thin layers of aluminum sheets with a honeycomb core made from aluminum or other materials. This sandwich structure provides exceptional strength while minimizing weight, making it an ideal choice for applications where both properties are crucial. The honeycomb core design not only enhances structural integrity but also offers excellent insulation properties, making these panels suitable for a wide range of environments.

The aerospace industry is one of the primary beneficiaries of aluminum honeycomb panels. These panels are used extensively in aircraft interiors, including flooring, walls, and ceilings. The lightweight nature of aluminum honeycomb panels contributes to fuel efficiency, which is a critical factor in aviation. By reducing the overall weight of the aircraft, airlines can save on fuel costs and increase payload capacity.

- Aircraft Interiors: Honeycomb panels are used for cabin walls, ceilings, and floors, providing a lightweight yet durable solution.

- Cargo Hold Liners: The panels are also used in cargo holds to create lightweight and strong partitions.

- Structural Components: In some cases, aluminum honeycomb panels are used in the structural components of the aircraft, contributing to overall strength without adding significant weight.

In the automotive sector, aluminum honeycomb panels are increasingly used in vehicle construction. The automotive industry demands materials that are lightweight yet strong to improve fuel efficiency and performance. Honeycomb panels are utilized in various applications, including:

- Body Panels: Honeycomb panels are used in the construction of body panels, providing strength while reducing weight.

- Interior Components: These panels are also used in the interior of vehicles, such as door panels and dashboards, where lightweight materials are essential.

- Structural Reinforcements: In high-performance vehicles, aluminum honeycomb panels are used for structural reinforcements, enhancing safety without adding excessive weight.

The construction industry has embraced aluminum honeycomb panels for their versatility and performance. These panels are used in both commercial and residential buildings, providing a range of benefits.

- Facade Systems: Aluminum honeycomb panels are often used in building facades, offering aesthetic appeal and durability.

- Interior Partitions: The lightweight nature of these panels makes them ideal for interior partitions, allowing for flexible space configurations.

- Ceiling Systems: Honeycomb panels are also used in ceiling systems, providing acoustic insulation and a modern look.

The marine industry benefits significantly from aluminum honeycomb panels due to their resistance to corrosion and lightweight properties. These panels are used in various applications on boats and ships.

- Boat Interiors: Honeycomb panels are used in the construction of boat interiors, including walls and ceilings, where weight reduction is crucial.

- Decking: The panels can also be used for decking, providing a strong and lightweight solution that resists water damage.

- Structural Components: In larger vessels, aluminum honeycomb panels are used for structural components, contributing to overall strength and stability.

Beyond aerospace and automotive, the transportation industry utilizes aluminum honeycomb panels in various forms of transport, including trains and buses.

- Train Interiors: Honeycomb panels are used in train interiors for walls and ceilings, providing a lightweight solution that enhances passenger comfort.

- Bus Construction: In buses, these panels are used for body construction and interior components, improving fuel efficiency and reducing wear on the vehicle.

- Cargo Transport: The panels are also used in cargo transport vehicles, providing lightweight and durable solutions for cargo holds.

The electronics industry has found a use for aluminum honeycomb panels in various applications, particularly in the manufacturing of electronic devices and components.

- Heat Sinks: Honeycomb panels are used in heat sinks for electronic devices, providing excellent thermal management.

- Enclosures: The panels are also used in the construction of enclosures for sensitive electronic equipment, offering protection while minimizing weight.

- Support Structures: In some cases, aluminum honeycomb panels are used as support structures for electronic components, enhancing stability and performance.

The furniture industry has also embraced aluminum honeycomb panels for their lightweight and durable properties. These panels are used in various furniture applications, providing both functionality and aesthetic appeal.

- Tables and Desks: Honeycomb panels are used in the construction of tables and desks, offering a lightweight yet sturdy solution.

- Cabinets and Shelving: The panels are also used in cabinets and shelving units, providing strength without adding excessive weight.

- Seating: In some cases, aluminum honeycomb panels are used in seating solutions, enhancing comfort and durability.

The advantages of aluminum honeycomb panels extend beyond their lightweight and strength characteristics. Here are some additional benefits that make them a preferred choice across various industries:

- Thermal Insulation: The honeycomb structure provides excellent thermal insulation, making these panels ideal for energy-efficient buildings and vehicles.

- Acoustic Insulation: Aluminum honeycomb panels can effectively reduce noise, making them suitable for applications where sound control is essential, such as in theaters and concert halls.

- Corrosion Resistance: Aluminum is naturally resistant to corrosion, which enhances the durability of honeycomb panels in harsh environments, such as marine applications.

- Sustainability: Aluminum is a recyclable material, and the use of honeycomb panels can contribute to sustainable building practices by reducing material waste and energy consumption.

Aluminum honeycomb structural panels have proven to be a versatile and valuable material across various industries. Their lightweight, high strength, and excellent insulation properties make them ideal for applications in aerospace, automotive, construction, marine, transportation, electronics, and furniture. As industries continue to seek innovative solutions to improve efficiency and performance, the demand for aluminum honeycomb panels is expected to grow.

Aluminum honeycomb panels consist of two thin layers of aluminum sheets with a honeycomb core made from aluminum or other materials.

They are lightweight and strong, which helps improve fuel efficiency and reduce overall aircraft weight.

Yes, they are resistant to corrosion and are used in boat interiors, decking, and structural components.

They provide aesthetic appeal, durability, and flexibility for interior partitions and facade systems.

Their excellent insulation properties help reduce energy consumption in heating and cooling applications.

Are Aluminum Composite Panels Weather-Resistant in Singapore’s Climate?

Is Aluminum Composite Panel Section Waterproof And Fire Resistant?

Is Aluminium Composite Panel Wall Cladding Worth The Investment?

Are Aluminium Composite Panels Weatherproof in The UK Climate?

Can You Import Aluminium Composite Panel Textures into SketchUp Easily?