Views: 2 Author: Site Editor Publish Time: 2023-02-06 Origin: Site

Aluminum-plastic panel composition and structure: An aluminum-plastic panel is a new form of ornamental material with several exceptional qualities. Soon after its release, it was widely employed in curtain walls, indoor and outdoor decorating, and other fields, ushering in a new era of contemporary architectural decoration.

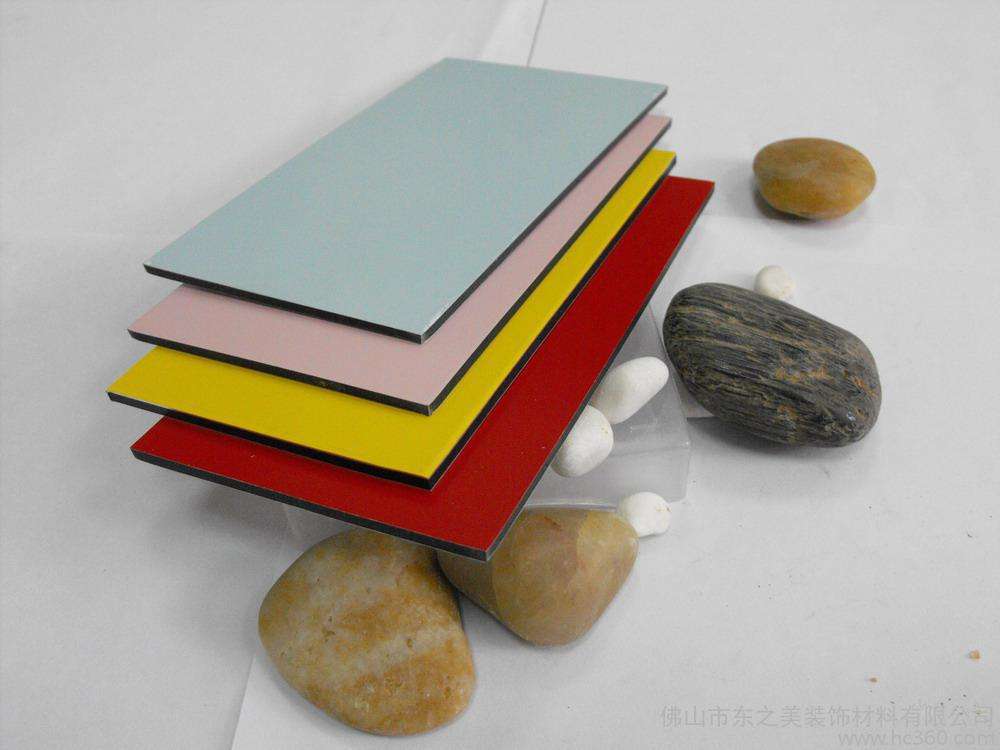

A panel consisting of aluminum and plastic is referred to as an aluminum-plastic panel. It is a plate comprised of an aluminum plate and the plastic core material that has been joined and compounded by a unique glue under specific production conditions. Typically, the front and back metal plates are coated first before being compounded with plastic core material. The front panel is often coated with a decorative coating, while the back panel is coated with a protective coating. In terms of structure, the aluminum-plastic panel is often a sandwich structure. This is a powerful metaphor. A plastic core material layer is placed between two layers of aluminum panels. Aluminum-plastic panels have a significantly more intricate construction.

Aluminum-plastic panel classification and specifications:

Aluminum-plastic panels come in a variety of shapes and sizes, and they are relatively new materials. As a result, there is currently no consistent classification approach. They are often classed based on their intended application, product function, and surface decorating impact.

(1) Purpose-based classification:

a. Aluminum-plastic panels for curtain wall construction:

The top and lower aluminum plates must have a minimum thickness of 0.50mm, and the total thickness must be at least 4mm. The aluminum material should meet the GB/T 3880 standards. In general, aluminum alloy plates from the 3000 and 5000 series should be utilized, with a fluorocarbon resin coating.

b. Aluminum-plastic panels for exterior wall decoration and advertising: The upper and lower aluminum plates are constructed of anti-rust aluminum with a thickness of at least 0.20mm, with a total thickness of at least 4mm. The coating is often made of fluorocarbon or polyester.

c. Indoor aluminum-plastic panels: Upper and lower aluminum plates are typically made of aluminum plates with a thickness of 0.20mm and a minimum thickness of 0.10mm, with a total thickness of 3mm. The coating is made of polyester or acrylic.

(2) Product function classification:

a. Fireboard: A flame-retardant core material is chosen, and the product's combustion performance meets the flame-retardant (B1 grade) or non-combustible (A grade); at the same time, other performance indicators must match the technical criteria of aluminum-plastic panels.

b. Antibacterial and mildew-proof aluminum-plastic panels: Coat aluminum-plastic panels with antibacterial and bactericidal coatings to restrict microbial activity and reproduction and, ultimately, to kill microorganisms.

c. Aluminum-plastic antistatic panel:

The surface resistivity of the antistatic aluminum-plastic panel is less than 109, which is lower than that of typical aluminum-plastic panels. As a result, it is difficult to generate static electricity and for dust in the air to attach to its surface.

(3) Surface decoration impact classification:

a. Coated ornamental aluminum-plastic panel: Coating the surface of the aluminum plate with various decorative coatings. Fluorocarbon, polyester, and acrylic coatings are commonly utilized, with metallic colors, plain colors, pearlescent colors, fluorescent colors, and other ornamental colors being the most prevalent variations on the market.

b. Colored oxidized aluminum-plastic panel: The aluminum alloy panel is processed in time by anodic oxidation and has unique colors such as rose red and bronze, which have a special decorative effect.

c. Film